Modular Cable System (MCS) Components for Artificial Arm Prosthetics

ToughWare’s high-performance Modular Cable System (MCS) components are designed for use with our rotary-swaged and polished stainless cable and low-friction polymer liner housing but will accept other manufacturers’ 1/16” diameter cable. They are highly versatile and reusable, eliminating the need for specialty swaging tools and one-shot crimp-style cable termination fittings. These heavy-duty components install with simple tools and are ideal for field installation and service in regions where access to tools or other equipment is limited.

Description

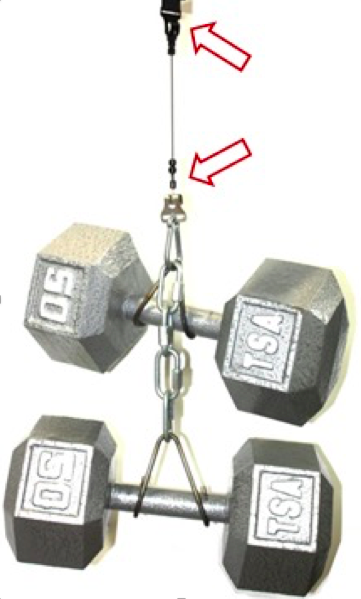

ToughWare’s high-performance Modular Cable System (MCS) components are designed for use with our rotary-swaged and polished stainless cable and low-friction polymer liner housing but will accept other manufacturers’ 1/16” diameter cable. They are highly versatile and reusable, eliminating the need for specialty swaging tools and one-shot crimp-style cable termination fittings. These heavy-duty components install with simple tools and are ideal for field installation and service in regions where access to tools or other equipment is limited. Designed for strength and safety, the harness hanger and cable termination fittings will not corrode or degrade with exposure to fine dust, sweat, or saltwater. Our bent ball termination fitting replaces troublesome triple-swivels, connecting directly to all ToughWare terminal devices and most standard body-powered split hooks. A detachable hanger system lets the user separate their harness from the rest of their prosthesis for adjustments, repairs, and laundering. Additionally, ToughWare’s new retainer and crossbar components enable clinicians to retrofit MCS components into existing prostheses to achieve even better performance and reliability.

MCS Parts

Figure-of-Nine Harness (Black)

Quick-Disconnect (QD) Detachable Harness Hanger

Quick-Disconnect (QD) Detachable Ball Terminal—Short Version

Quick-Disconnect (QD) Detachable Ball Terminal—Bent Version

Quick-Disconnect (QD) KIT

Rubber Grommets

Raw Cable & Housing

Insurance L Code Justifications